| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | V-motor |

| Model Number : | VIRIS107-13 |

| Certification : | RoHS |

| Price : | US$8~17 |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 100000/month |

| Delivery Time : | 15 days |

IRIS detects light intensity through sensors inside the camera. After calculations, the system determines how much the aperture needs to be opened. The system controls the engine in the IRIS lens to dynamically and precisely control the aperture size. In order to achieve the best photo effect.

This product is a dual-drive integrated (IRIS & IR-CUT) IRIS: two blades, one is blue glass, the other is AR glass, which can be connected to IR-cut through a carrier to achieve different filter modes. The engine is connected via FPC and Hall sensors, which can dynamically and accurately adjust the aperture size.

P-IRIS dynamically and precisely controls aperture size by controlling stepper motors within the P-IRIS lens. Unlike DC-IRIS, where the main task is to constantly adjust the aperture size, the main purpose of P-IRIS is to set the optimal aperture position, so that most of the center of the lens and the part that works best is utilized, and this position has a large optical error . reduce. Small size, thus improving image quality. P-IrIS requires the use of gain and exposure time to manage small changes in light to further optimize image quality, maintaining the optimal aperture position for as long as possible. However, when the ability to adjust gain and exposure time is exceeded, P-IRIS adjusts the iris to different positions. This product is a dual driver integrated (IRIS & IR-CUT) IRIS: 2 pieces, FPC connection (including HALL) IR-CUT: 1 switch board, 1 blue glass, 1 AR glass, FPC connection.

1) Camera

2) Optical instruments

3) Precision medical devices

4) Automatic door locks

Other precise control application

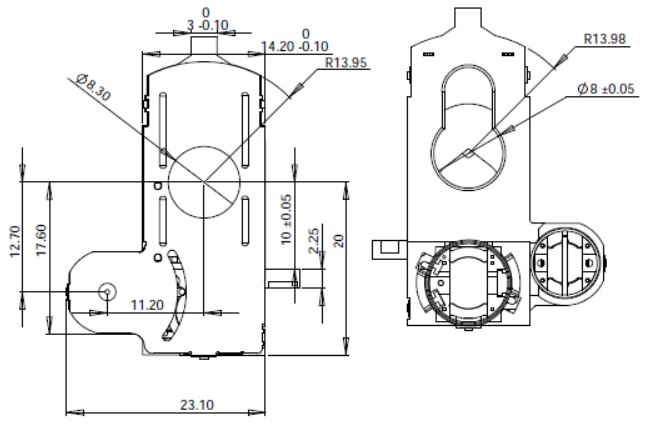

| Model No. | VIRIS107-13 motor |

| Motor type | IRIS ir cut |

| Phase No. | 2 phases |

| Step angle | 18 degrees |

| Phase resistance | 81 Ohms/phase |

| Excitation method | 2-2 bipolar drive |

| Rated voltage | 5 - 12 V DC |

| Lead screw type | M2P0.4 |

| Stroke | 21mm |

| Pull-out thrust | Over 1.8 g.cm at 960PPS |

| Pull-in torque | Over 1.6g.cm at 960PPS |

IRIS working principle:

Product display:

AR sheet transmittance (T-λ curve see above):400~1100nm Tmin>92% Tave≥96%

Transmittance (T-λ curve as above):

1. question:What is IR-CUT

Answer:IR-CUT can be understood as CMOS "glasses", IR-CUT includes "glasses" and "glasses remover", "glasses" is a filter, "glasses remover" is the mechanical structure of IR-CUT.

Under normal conditions, the lens has two pieces of glass and a bracket, one for filtering infrared light during the day, and the other for full light transmission at night. The two lenses are controlled by an IR-CUT motor (or other type of engine), and they work in turns. During the day, an infrared filter is used to prevent the image from being skewed. At night, full transparency is used to increase sensitivity. IR=Infrared=Infrared.

CUT = filter, subtract

2. question:When to use IR-CUT

Answer:IPC network cameras normally have high requirements for images. They require that the images are not biased during the day, and the night vision with infrared lights is good at night, so IR-CUT is required.

3. question:Special requirement for using IR-CUT

Answer: When using an IR-CUT with infrared light, it is necessary to output a sync signal from the light board to the CMOS board to "tell" the CMOS board whether the infrared light is currently on or off. Required for all CMOS with IR lamps with IR-CUT.

|